Background Introduction:

The radio frequency power supply is a core component of plasma processing equipment. The radio frequency power supply is the core component for generating plasma and has a significant impact on the processing capacity and effect of the plasma processing equipment. The main influencing areas include etching in semiconductors, film deposition, ion implantation, cleaning and etching removal, etc., as well as the film deposition process in photovoltaics. The performance of the radio frequency power supply is crucial for the quality and stability of the formed plasma, and therefore has extremely high requirements for output mode, output efficiency, and output stability. It is one of the high-tech barriers components among semiconductor components.

Due to its high technical barriers and complex R&D requirements, the radio frequency power supply market has long been monopolized by American companies. The major players are the American company MKS Instrument and Advanced Energy.

The Sino-US trade friction has spurred the domestic substitution of radio frequency power supplies, and Yingjie Electric and Hengyun Chang have taken the lead in research and development. Others: Wuhan Fan Gu and Shenzhou Semiconductor.

RF power supply application 1: Plasma etching equipment

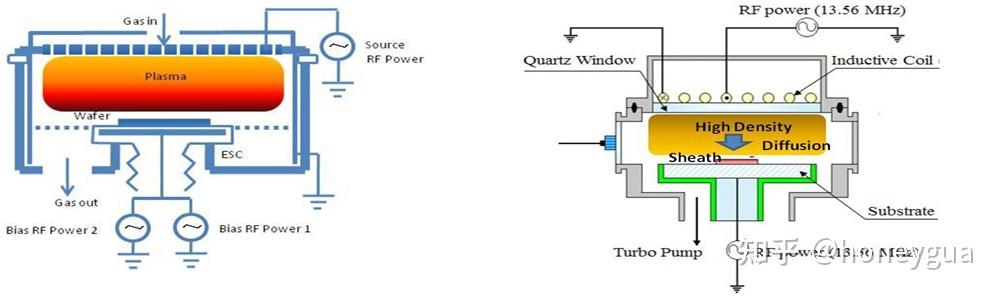

In a single-chamber etching equipment, typically 2-3 RF power supplies are used, and 1 high-frequency power supply serves as the Source, generating plasma; 1-2 low-frequency power supplies act as the Bias source to apply a bias electric field and accelerate the ions. The advantage of using the high-frequency power supply as the Source is that it enables more collisions among the particles in the plasma, thereby achieving a higher density of particles; while using the low-frequency power supply as the Bias source is more conducive to giving the particles higher speed and kinetic energy, enabling the ions to have stronger impact capability.

The left figure shows the application of the radio frequency power supply on the CCP, while the right figure shows its application on the ICP.

RF power supply application 2: PECVD (Plasma Enhanced Chemical Vapor Deposition) equipment for thin film deposition

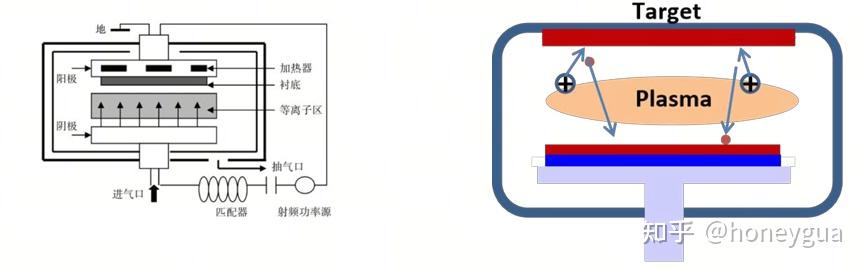

PECVD typically involves generating a plasma by subjecting the material to be deposited to radio frequency (RF) energy, and then completing the deposition process on the silicon wafer through chemical reactions. In PVD, a plasma needs to be formed first, and then under the action of an opposing electric field, the plasma is bombarded onto the target material at the top of the chamber to knock off the target particles and complete the deposition. In PEALD, plasma is also used to enhance the deposition capability.

Left figure shows the application of PECVD, while the right figure shows the application of PVD.

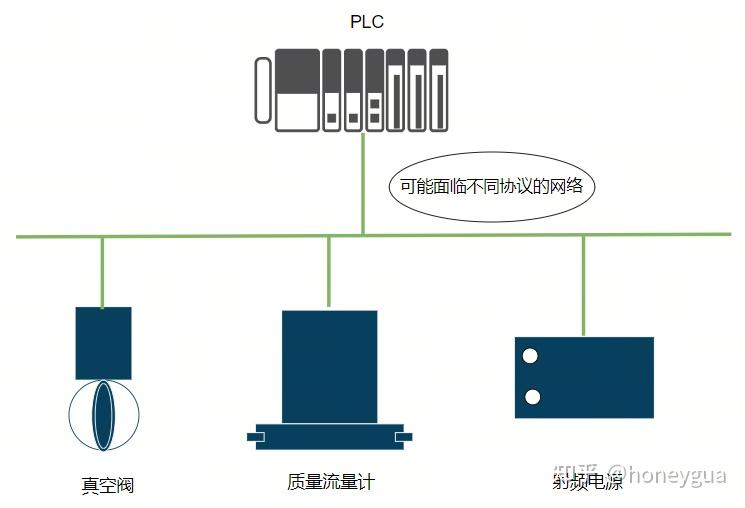

We can see that whether it is Application 1 or Application 2, the RF power supply is merely a component within the entire machine. Take the etching equipment as an example, apart from the RF power supply, the machine also contains vacuum valves, mass flow meters, and a set of main control equipment, usually a PLC. The basic architecture is as follows:

We know that typically, different manufacturers' PLCs have different industrial communication protocols. For instance, Siemens PLCs usually use Profinet and Profibus DP protocols, while Beihua PLCs generally use EtherCAT communication protocol.

In the early stage of semiconductor development, there were no standards for communication protocols. Siemens' Profibus DP was widely used in the industry. Later, as the control systems of equipment required fast and high-precision information transmission, under this background, SEMI incorporated DeviceNet as an application standard into the semiconductor equipment system very early. With the increasing number of internal devices in semiconductor machines, larger amounts of data transmission, faster transmission speeds, and more servo systems, in 2007, SEMI included EtherCAT in the semiconductor communication standards.

Therefore, for semiconductor equipment (such as RF power supplies), there may be a need for multiple communication protocols.